When we talk about beautiful and long-lasting flooring, oak wood flooring often tops the list for homeowners seeking warmth, durability, and timeless character. But as design preferences shift toward wider and longer planks, the construction of what's under the surface becomes just as important as how it looks on top.

Previously, we’ve explored herringbone flooring patterns and their appeal—now it’s time to look at what holds the floor together: the structure. Enter the world of engineered hardwood, particularly 3-ply oak flooring, and let’s break down why it’s making waves.

What Is Engineered Hardwood?

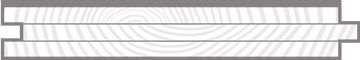

Engineered wood flooring is made up of multiple layers, combining natural hardwood (usually a wood veneer) with structural layers beneath. This layered design makes it more stable than solid hardwood, especially in areas with temperature and humidity changes—think basements, condos, or Vancouver’s moody weather.

At the top, you get real oak wood or other hardwood species—this is what you see and feel. Underneath? That’s where the magic happens.

Meet the Core: 3-Ply vs. Plywood

Let’s talk structure—because that’s where flooring either holds strong or starts to fail.

1. Plywood Core (Multi-Ply)

This type uses multiple thin wood veneer sheets in alternating directions. This “cross-grain” method adds strength and reduces the chance of warping. Think of it like a stack of pancakes—each layer adds strength and resilience.

- Great for general stability

- Supports thinner or thicker wood veneer tops

- Often used in mid- to high-end engineered hardwood lines

2. 3-Ply Construction

This is a more refined sandwich:

- Top layer: Natural oak wood veneer

- Core: Solid softwood or HDF, laid crosswise for strength

- Bottom layer: Balancing wood or veneer wood

Why is this a game changer? Because the top and bottom layers are designed to expand and contract at the same rate. This means fewer issues like cupping, gapping, or floorboards that just won't stay flat.

In fact, 3-ply flooring shines when paired with wider and longer planks—exactly the style many homeowners crave today.

Why 3-Ply Oak Wood Flooring Is Worth It

Let’s get to the point—why should you care?

-

Dimensional Stability

The perpendicular grain layout in 3-ply construction helps resist movement. That means fewer headaches with seasonal changes. -

Genuine Oak Surface

You’re not sacrificing style for performance. You still get that premium oak wood look, feel, and texture. -

Stronger, Smarter Build

The top wood veneer is typically thicker (often 3–4 mm), offering more opportunities for refinishing—so your floor lasts longer. -

Sustainable & Efficient

With a veneer wood top layer, less solid hardwood is used compared to traditional planks. More eco-conscious, less waste.

Real Oak Look. Engineered Confidence.

From classic wood panels to trendy extra-wide planks, modern flooring is about more than just looks. It's about making sure your space feels right—and lasts.

Whether you’re eyeing a minimalist Scandinavian interior or a rich traditional design, engineered hardwood flooring with oak veneer and solid 3-ply construction delivers strength beneath style.

And if you’re wondering about installation? Most 3-ply engineered floors are compatible with multiple install methods—floating, glue-down, or nail-down—making your flooring journey smoother from start to finish.

If you’re investing in wood flooring that performs as beautifully as it looks, 3-ply oak engineered hardwood should absolutely be on your radar. It’s the perfect balance of design, strength, and smart material use.